Your cart is currently empty!

Advanced Tank Gauging

Discover Our Cutting-Edge Solutions

This section describes the key features briefly.

Precise Measurements

Accurately track volume, mass, temperature, and more with our advanced gauging systems.

Enhanced Monitoring

Streamline inventory management with real-time data and reliable monitoring tools.

Innovative Software

Optimize operations with our intuitive software for bulk storage tank analysis.

Comprehensive Overview of Tank Gauging Metrics

This section provides critical insights into performance metrics, system reliability, and operational achievements.

120

Precision Data

This metric demonstrates the accuracy of our gauging solutions, ensuring reliable measurements.

7500+

Global Reach

This metric highlights our extensive installation base, showcasing industry trust and scalability.

450

System Uptime

This figure underscores the durability and dependability of our advanced monitoring systems.

Advanced Tank Gauging Solutions Overview

Explore our range of advanced tank gauging services, designed to ensure precision, efficiency, and customer satisfaction.

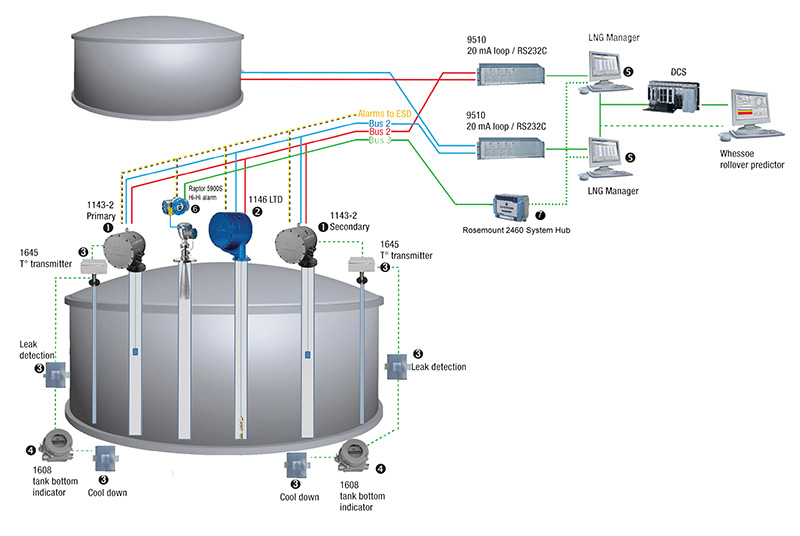

Multi-Function Tank Gauging Systems

Engineered for bulk storage tanks and vessels, these systems provide precise measurements for inventory management, safety, and operational efficiency

Key Features:

Support for in-tank blending and product stratification analysis.

Accurate measurement of volume, mass, level, temperature, density, and water content.

Overfill and rupture protection compliant with industry standards.

Vapor monitoring and leak detection capabilities.

Mechanical Tank Gauges

Reliable float and tape instruments designed for continuous level measurement in various storage tanks.

Key Features:

Easy installation and maintenance with removable components.

Accurate level readings with optional dual calibration assemblies.

Durable construction suitable for low-pressure applications.

Liquid Level Indicators

Cost-effective visual level indicators mounted externally, connected to internal floats, providing clear and accurate readings.

Key Features:

Optional liquid seals to prevent vapor escape.

Large, easy-to-read numerals visible from a distance.

Available in various materials to suit different environmental conditions.

Digital Transmitters & Encoders

Devices that convert mechanical gauge data into digital signals for integration with control systems.

Key Features:

Provides continuous level and temperature data to host systems.

Supports multiple communication protocols (e.g., MODBUS, Tankway).

Explosion-proof housings suitable for hazardous areas.

Tank Gauging Software Solutions

Comprehensive software platforms designed for monitoring and managing tank data in real-time.

Key Features:

Accessible via LAN, WAN, or cloud interfaces on various smart devices

User permissions and system configuration databases.

Continuous polling of configured instruments with alarm processing.

Historical event logging and customizable reports.

Discover Our Tank Gauging Applications

This section presents a detailed look at our innovative tank gauging systems, emphasizing accuracy and reliability.

1. Rain and Snow on External Floating Roofs (EFR)

Monitoring and managing the accumulation of rain and snow on external floating roofs to prevent structural stress and potential failures.

2. Historian Integration

Implementing systems that record and store historical data from tank gauging operations, enabling trend analysis and informed decision-making.

3. Leak Detection

Utilizing advanced sensors and monitoring techniques to detect leaks in storage tanks promptly, ensuring environmental safety and compliance.

4. Overfill Protection

Deploying high-level alarm systems and automated shutdown mechanisms to prevent tank overfills, safeguarding against spills and associated hazards

5. Rupture Protection

Installing pressure and vacuum relief devices to protect tanks from rupture due to over-pressurization or vacuum conditions

6. Vapor Monitoring

Continuous monitoring of vapor emissions from storage tanks to detect and control volatile organic compound (VOC) releases, ensuring air quality standards are met.

7. Water Draw-off

Implementing systems to remove accumulated water from the bottom of storage tanks, maintaining product quality and preventing corrosion.

8. In-Tank Blending

Facilitating the blending of different products within a single tank to achieve desired specifications, improving operational efficiency.

9. Wine Tanks

Specialized gauging solutions tailored for the wine industry, focusing on precise level measurement and quality preservation during storage.

The accuracy of their tank gauging systems has transformed our client operations, delivering reliable results every time.